What Nails To Use With Azek Trim Board

Cutting and Installing Plastic Trim

Learn the secrets of successful PVC trim installation.

![]() Time

Time

Multiple Days

![]() Complexity

Complexity

Intermediate

![]() Cost

Cost

Varies

Introduction

PVC trim looks and cuts similar wood and it lasts forever, but there are a few special installation techniques you need to know about to install it successfully.

Tools Required

Materials Required

- 100% acrylic outside paint

- Acrylic caulk

- Exterior filler

- Long-setting PVC cement

- PVC trim

- Stainless steel trim-head screws

Tired of scraping and repainting your trim? Or disheartened when you detect that your trim has rotted and volition no longer hold pigment? Then step back and consider the advantages of replacing those problem boards with PVC azek trim—your worries will exist over.

Cellular PVC board (polyvinyl chloride) azek trim is a shut cousin of the familiar white plastic plumbing pipes. (The "cellular" part just means it's filled with zillions of tiny air bubbling to make the material lighter and less expensive to industry.) But unlike its cousin, PVC azek trim is specially formulated to make information technology resistant to sunlight, hold paint well and piece of cake to work with.

PVC azek trim looks just like wood (well, flawless wood) and lasts nearly forever. PVC azek trim impervious to rot and insect attack and doesn't absorb h2o. It holds pigment well because water tin can't penetrate the material behind the pigment. And if you lot like the look of white trim, you lot may non have to paint information technology at all (more than on this afterward). It's an especially skilful substitute for forest trim in areas that are highly exposed to water, such every bit corner trim boards and door trim that's near the ground or unprotected by an overhang.

Although you install cellular PVC azek trim nigh like wood, there are a few crucial differences. In this story, we'll show y'all those special cutting, joining and fastening techniques and so your PVC azek trim will perform flawlessly for the life of your home. Don't worry—in that location aren't any fancy tools or skills required. If yous've cutting and installed wood trim before, you accept the moxie to work with PVC trim boards.

PVC trim is sold in 5/4 (1-in.) and 4/four (3/4-in.) thicknesses in the common widths constitute with wood. But the selection may be limited. You'll probably accept to special-order some thicknesses and widths. PVC trim boards are sometimes just sold in 18-ft. lengths, so you lot may want to have your order delivered. About companies offering material that has an embossed wood grain side and a smooth side, so you tin choose the look you want. Don't confuse cellular vinyl trim with polyurethane-cadre, vinyl-coated products. While they also are highly durable depression-maintenance products, their installation techniques are unlike.

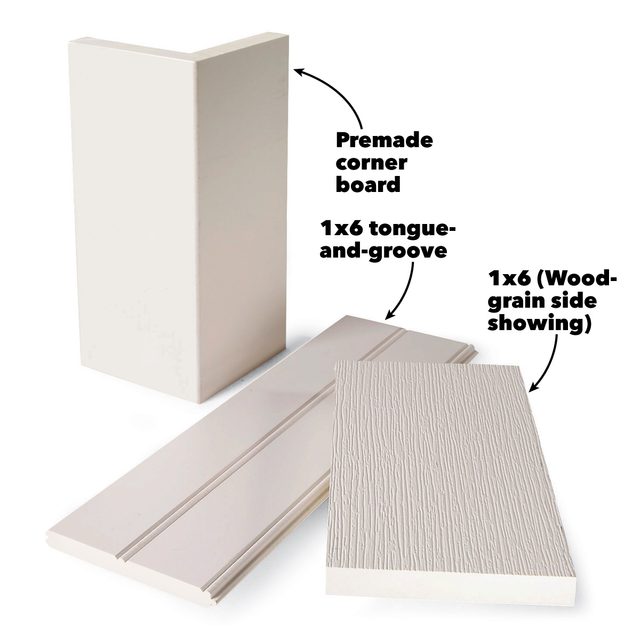

PVC trim isn't cheap; await to pay about the same toll y'all'd pay for articulate, knot-free wood. Other PVC products are as well available, including preformed outside corners, tongue-and-groove boards, and sheet goods that you tin can carve upward and work just like plywood.

Discover PVC trim by contacting lumberyards in your area.

Project step-by-step (nine)

Pace ane

Cutting with carbide-tipped saw blades and $.25

Cut PVC trim boards with the same manus and power tools that you use for wood. Only utilize but carbide-tipped saw blades; plainly steel ones will slow speedily. In general, the more teeth a blade has, the smoother the cut edges will exist. We recommend standard combination saw blades. You can easily rout decorative edges or grooves with routers or shapers, but use carbide-edged bits as well.

Sawn edges aren't every bit easy to sand as wood. So if possible, programme your work so that newly cutting edges will barrel against siding, soffits or other trim, and permit the smoother factory edge show wherever possible. Sanding isn't always necessary, particularly if you programme to paint. But sand exposed edges that are highly visible, like near the forepart door. Employ a random orbital sander with 100-grit paper. Chugalug sanding doesn't work well because the friction from the belt melts the plastic rather than smoothing information technology.

Step two

Fasten PVC trim with stainless steel screws or hot-dipped siding nails

When information technology comes to choosing your fasteners, don't scrimp by using fasteners that won't last every bit long as the vinyl trim. Stainless steel screws with small stop heads are the best pick considering they'll never corrode. You can also utilise hot-dipped galvanized nails, but they may corrode and stain the trim over time. If you desire a flawless stop, choose screws, countersink them slightly, and then utilise an exterior filler to hide the screw heads. In areas that are completely protected from water, like under a soffit, you lot can use a 15-gauge air nailer with galvanized nails and fill the holes with paintable caulk or filler.

PVC tends to expand and contract with temperature changes, so fasten information technology well. Drive screws or nails into framing only, never but to the capsule. Select fastener lengths that will penetrate at least 1-ane/2 in. into the framing. No predrilling or countersinking is necessary if the temperature is over 40 degrees F when you install the trim. But lower temperatures call for both drilling and countersinking; otherwise the vinyl may divide. Place fasteners every 16 in. at both sides of the trim, spacing them about 1/two in. from the edges. If you're using 10-in. or wider trim, add another fastener in the centre.

Follow all of the flashing techniques that you would with wood trim. Yous still want to prevent water from penetrating betwixt the PVC trim boards and the wall sheathing backside.

Footstep three

Cement seams for sturdy, watertight joints

One advantage of PVC is that you can "weld" joints to keep them tight and prevent water from penetrating behind the trim. Manufacturers recommend a special type of PVC cement that has a longer "open time" than the type of cement that plumbers use on plastic pipes. You can purchase this cement wherever you purchase the trim. Y'all'll have about five minutes of working time to clamp and fasten the joints before the cement sets. Smear a niggling cement on both surfaces and so clamp or screw the joint together. Wipe off any excess right away with a clammy rag; different PVC pipe cement, it's water soluble and won't mar finished surfaces if yous remove it immediately.

Step 4

Preassemble window and door trim

Prebuild PVC trim assemblies and so install them as a unit rather than a piece at a time as you would with woods. This volition accept a footling longer merely will upshot in perfectly tight joints that won't need caulk. Cement and spiral terminate joints like miters and butt joints. Longer joints like corner boards can be simply cemented and clamped.

Pocket screws are the best method of joining corners when y'all're cementing window and door trim assemblies (Photos 1 and 2). Use the coarse-threaded version of pocket screws. Cutting miters to fit and dry out-fit your cuts to bank check the joints and lengths. Measure carefully when applying trim around vinyl or aluminum-clad windows to leave a 1/8-in. expansion gap between the trim and frame for caulk.

Step 5

Preassemble corner PVC boards

Some manufacturers offer pre-made trim for outside corners, but it's somewhat pricey. It'due south easy to brand your own. Get-go by ripping 45-caste bevels on one edge of each lath on a table saw. And then push the bevel tips together tightly and tape the boards together with packaging or duct tape. Apply cement to both bevels, and then fold the boards together and clench the joint for about fifteen minutes with more than strips of record.

Footstep 6

Leave expansion gaps on long pieces

PVC trim boards will aggrandize and contract with broad variations in temperature. If you're installing trim in temps college than lxxx degrees F, cutting pieces to fit tightly. If it's between 60 and 80 degrees, get out a ane/sixteen-in. gap for every 18 ft. of length. Below 60 degrees, exit a ane/8-in. gap. After installation, cover the gap with acrylic or urethane caulk. Avoid silicone-based caulks; they don't adhere well to vinyl.

Pace 7

Fill fastener holes earlier you pigment

Fill small holes with an exterior filler and lightly sand it polish after it dries. Or use a paintable caulk and smooth information technology with your finger. Fill larger holes or damaged areas with auto body filler, and once more, sand it after information technology cures.

Step viii

Splice long trim pieces with scarf joints

Splice long pieces of PVC trim with "scarf joints," that is, overlapping 45-degree joints. Cut the first piece of trim to fall just short of a stud so the 2d overlapping trim piece tin can be fastened to the stud an inch or so from the stop to prevent splitting.

Stride 9

Paint vinyl trim with 100 percentage acrylic outside paint

Although painting PVC trim boards isn't necessary, we recommend it. Otherwise your trim will look stark white and you may see filler over holes that's not an exact color lucifer. And the edges and ends (especially ones that you accept cut or routed) volition collect dirt and begin to look gray over fourth dimension.

There'due south no hurry for painting subsequently installation; you can wait as long as you want. PVC boards won't weather or lose its ability to hold paint. Earlier you paint, utilize mild detergent to make clean off crud and oils left over from treatment and make sure the surfaces are dry out. Then finish it with any exterior 100 percent acrylic pigment. Use lighter shades rather than darker shades. Dark colors tend to absorb more oestrus and increase expansion. Next, check out exterior painting tips you need to know.

Originally Published: February 22, 2021

Source: https://www.familyhandyman.com/project/cutting-installing-plastic-trim/

Posted by: christopherlettan72.blogspot.com

0 Response to "What Nails To Use With Azek Trim Board"

Post a Comment